Introduction

A’ight, listen up, squad! Ever wondered what’s the deal with rubber laser engraving machines? Well, get ready to vibe with me ’cause we’re about to spill the tea on these bad boys! Picture this: you got a sick pair of kicks or a dope phone case, and you wanna add your own flavor to ’em, right? That’s where these machines come in clutch, givin’ you the power to customize your stuff like a boss.

Yo, what’s up, squad! Let’s kick things off with a bang and dive into the world of rubber laser engraving machines. Get ready to level up your game and unleash your creativity like never before!

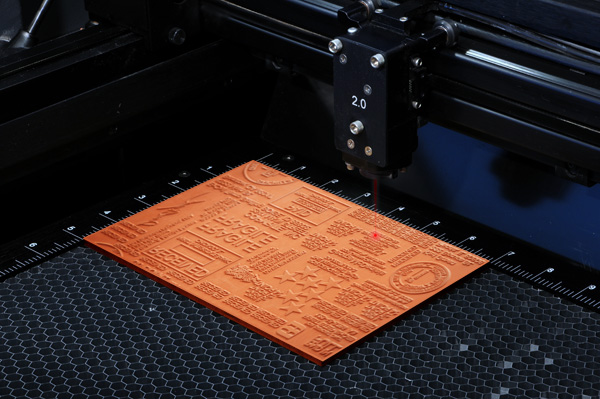

So, what’s all the hype about, you ask? Let me break it down for ya. These machines are straight-up game-changers when it comes to engraving and cutting rubber. They’re like the MVPs of personalization, takin’ your gear from basic to boujee in no time. With precision and finesse, they turn your ideas into reality, leavin’ you with designs that pop and stand out from the crowd.

Now, I know what you’re thinkin’: how do these babies even work? Well, it’s all about harnessing the power of lasers to etch and cut through rubber like butter. It’s some next-level stuff, my dudes. Just imagine wieldin’ that laser beam like a boss, creatin’ intricate designs and patterns with ease. Trust me, once you see these machines in action, you’ll be hooked for life. So, buckle up and get ready for a wild ride into the world of rubber laser engraving!

What’s the Buzz About Rubber Laser Engraving Machines?

Yo, peeps! Let’s talk about what’s up with rubber laser engraving machines, ya feel me? These bad boys are lit when it comes to jazzing up rubber stuff. I’m talking about customizing kicks, phones cases, and more with some serious swag. You wanna add your own flavor to your gear? These machines got your back, fam. They’re like the secret sauce to making your stuff stand out from the crowd, no cap.

Benefits of Rubber Laser Engraving:

- Flexibility: Rubber laser engraving offers mad flexibility, allowing you to customize designs and patterns on various rubber materials, from stamps to gaskets.

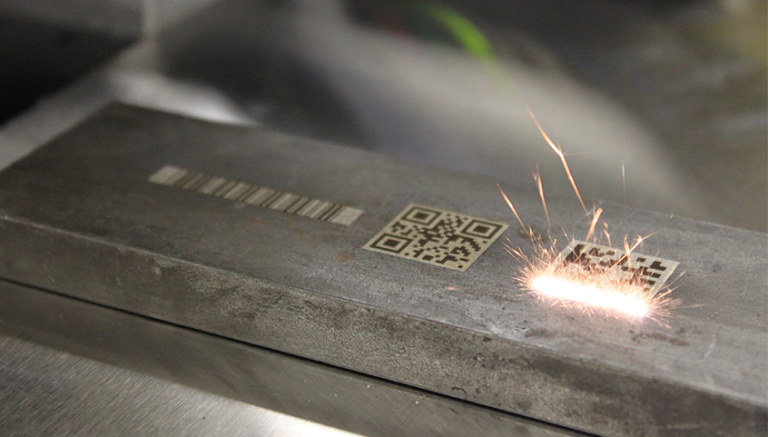

- Precision: With laser precision, you can achieve detailed and intricate designs with ease, making your creations stand out from the crowd.

- Efficiency: Say goodbye to time-consuming traditional methods – rubber laser engraving gets the job done in a fraction of the time, boosting your productivity.

Now, let’s break it down. How do these machines even do their thing? It’s all about harnessing the power of lasers, my dudes. They zap through rubber like it’s butter, carving out designs with precision that’ll blow your mind. It’s like having a laser wizard at your fingertips, turning your ideas into reality faster than you can say “dope.” So, if you’re lookin’ to level up your customization game, these machines are the move, straight up.

How Do Rubber Laser Engraving Machines Work?

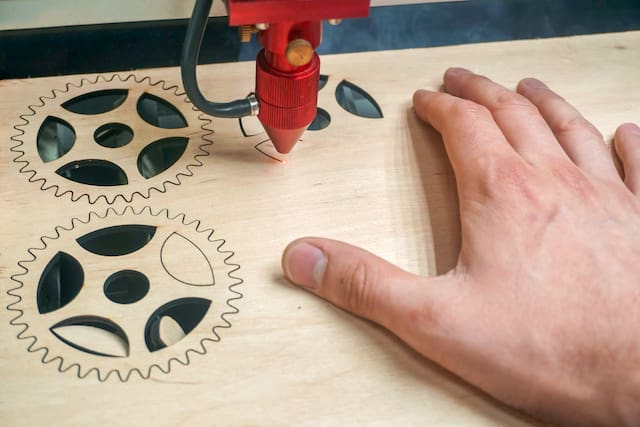

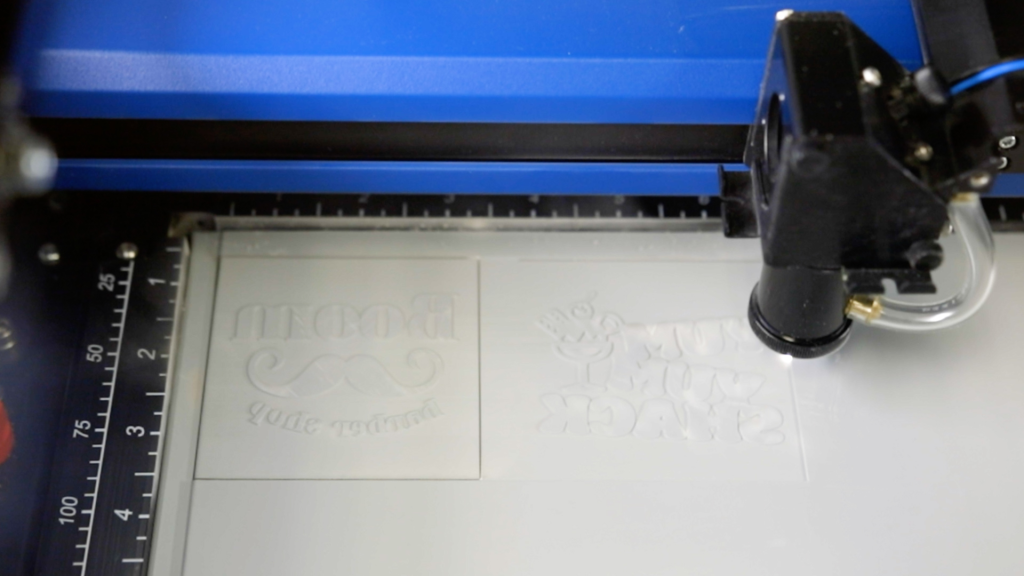

Alright, fam, let’s dive into the lowdown on how rubber laser engraving machines get down. Picture this: lasers are the real MVPs here, doing all the grunt work to make those sick designs pop. They’re like the artists of the future, carving out your vision with precision and style. And it’s not just about blasting rubber away randomly – nah, it’s all about finesse, controlling that laser beam like a boss to get those clean, sharp engravings that’ll make heads turn.

So, how does it all go down? First off, you gotta set up your design, whether it’s your logo, a sick graphic, or your favorite meme. Then, it’s game time – the laser gets to work, burning away the rubber layer by layer to reveal your masterpiece. It’s like watching magic happen right before your eyes, seeing your ideas come to life in real-time. And don’t stress if you’re new to the game – we got your back with a step-by-step breakdown that’ll have you slinging lasers like a pro in no time.

Applications of Rubber Laser Engraving:

- Custom Stamps: Create dope custom stamps for branding, personalizing gifts, or adding flair to your projects.

- Prototyping: Use rubber laser engraving to prototype new product designs quickly and accurately, saving you time and money in the long run.

- Art and Décor: Elevate your art game by using laser-engraved rubber to add unique textures and patterns to your masterpieces.

At the end of the day, rubber laser engraving machines are the ultimate tool for anyone looking to add some flair to their gear. Whether you’re repping your crew, promoting your brand, or just flexing your creativity, these machines are the key to making your mark in style. So, grab one, get creative, and let your imagination run wild – the laser’s the limit, my friends.

Troubleshooting Guide

Alright, check it out, peeps! When you’re cruising with your laser engraving machine and hit a bump in the road, you gotta be ready to troubleshoot like a boss. That’s where having a solid troubleshooting guide comes in clutch. It’s like having your back covered when things start to go sideways.

I’m talking about getting hip to the manufacturer’s troubleshooting guide, fam. This ain’t just some dusty manual sitting on a shelf collecting cobwebs. Nah, it’s your lifeline when you’re facing tech glitches or gremlins messing with your machine. With this guide in hand, you can zap those problems before they throw a wrench in your workflow.

- Manufacturer’s troubleshooting guide: This guide is like your tech bible, helping you navigate through any glitches or hiccups your machine might encounter.

- Lifeline: Think of this guide as your lifeline, your go-to resource when you’re in a jam and need to troubleshoot issues pronto.

- Tech glitches: These pesky little problems can throw a wrench in your plans, but with the troubleshooting guide, you’ll be equipped to handle them like a pro.

- Downtime: Ain’t nobody got time for downtime! With the troubleshooting guide, you can minimize downtime and keep your production rolling smoothly.

- Secret weapon: Consider the troubleshooting guide your secret weapon, empowering you to tackle any challenges that come your way with confidence and swagger.

Think about it, homies. Time is money, and downtime ain’t nobody’s friend. By knowing your way around the troubleshooting guide, you’re arming yourself with the knowledge to squash issues fast and keep your production on track. It’s like having a secret weapon in your arsenal, ready to tackle whatever curveballs the machine throws your way.

Choosing the Right Rubber Laser Engraving Machine

Alright, fam, let’s talk shop about finding the sickest rubber laser engraving machine for your hustle. No cap, choosing the right one can make or break your grind, so you gotta stay woke. First things first, it’s all about knowing your needs – whether you’re cranking out custom kicks or tagging up phone cases, you gotta pick a machine that’s got the juice to handle your flow. From speed to precision, every feature counts, so don’t sleep on the deets.

Choosing the Right Rubber Laser Engraving Machine:

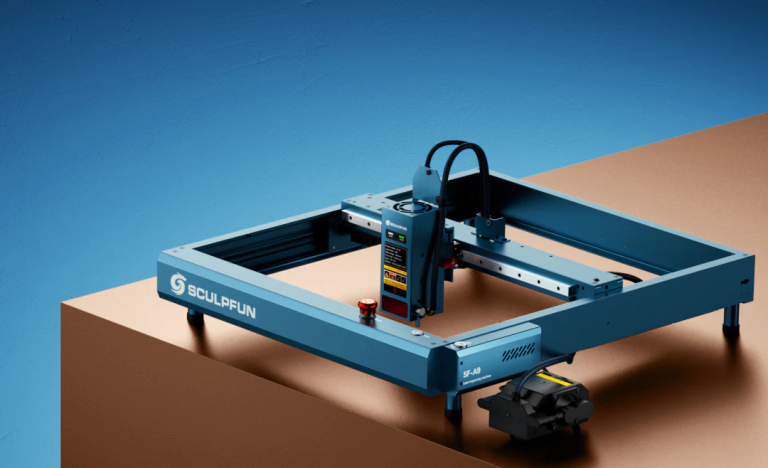

- Power and Speed: Consider the power and speed of the laser engraving machine to ensure it meets your project requirements.

- Workspace Size: Check the size of the engraving area to make sure it can accommodate your projects without limitations.

- Software Compatibility: Look for machines that are compatible with your preferred design software for seamless integration and workflow.

Next up, peep the key features like a boss. We’re talking about laser power, engraving area, and software compatibility – all the stuff that separates the players from the wannabes. You gotta make sure your machine can handle the heat, lay down those crisp lines, and vibe with your workflow. And don’t forget about the extras – from user-friendly interfaces to dope customer support, it’s the little things that can take your setup from basic to baller status.

| Feature | Description | Benefits | Example Models |

| Laser Power | Determines cutting depth and speed. Higher power allows for faster and deeper engraving. | Faster production, deeper engraving capabilities. | Model A: 50W, Model B: 100W |

| Engraving Area | Size of the working area. Larger area accommodates bigger pieces. | Ability to work on larger objects, more versatility. | Model X: 12″ x 12″, Model Y: 24″ x 18″ |

| Software Support | Compatibility with design software. Some machines come with proprietary software, while others are compatible with industry-standard programs. | Easy integration into existing workflow, access to advanced design features. | Model P: Proprietary software, Model Q: Compatible with Adobe Illustrator |

| Cooling System | Type of cooling mechanism, such as air or water cooling. Water cooling tends to be more efficient for prolonged use. | Longer machine lifespan, better performance during extended use. | Model M: Air cooling, Model N: Water cooling |

Last but not least, keep your eyes peeled for red flags. Ain’t nobody got time for janky machines that’ll leave you hanging mid-project. Look out for shady warranties, sketchy reviews, and anything else that feels off. Trust your gut, do your homework, and don’t settle for anything less than top-tier. At the end of the day, finding the right rubber laser engraving machine is all about staying on your grind and making moves like a true boss.

Tips and Tricks for Rubber Laser Engraving and Cutting

Alright, listen up, squad! It’s time to step up your game when it comes to rubber laser engraving and cutting. We’re about to drop some major keys to help you level up your skills and slay the engraving game like a pro. So grab your snacks, kick back, and let’s dive into these lit tips.

- Maintenance and Troubleshooting:

- Regular Cleaning: Keep your machine running smoothly by regularly cleaning the lens, mirrors, and other components to prevent buildup and maintain optimal performance.

- Calibration: Periodically calibrate your machine to ensure accurate engraving and consistent results.

- Troubleshooting Tips: Familiarize yourself with common issues and troubleshooting techniques to quickly address any hiccups and keep your workflow on track.

First off, let’s talk about avoiding those rookie mistakes. Ain’t nobody got time for messing up when you’re trying to get those flawless results. We’ll spill the tea on how to steer clear of the most common blunders and keep your engraving game on point. Whether it’s choosing the right materials or mastering your machine settings, we’ve got the inside scoop to help you stay on top of your game.

And don’t sleep on the importance of machine maintenance, fam. Keeping your gear in tip-top shape is key to ensuring those clean cuts and crisp engravings. We’ll hook you up with all the hacks and tricks to maintain your machine like a boss, so you can keep slaying the engraving game day in and day out. So get ready to elevate your skills and take your engraving hustle to the next level with these lit tips and tricks!

Conclusion

Yo, peeps! That’s a wrap on our journey through the world of rubber laser engraving machines. Now you’re all strapped with the know-how to level up your game and rock those projects like a boss. So don’t sleep on this knowledge, fam – it’s time to put it into action and let your creativity run wild. Get out there, show off those laser skills, and let that rubber shine like never before!